The Texi Plastic technical department works to find solutions and produce quality thermoplastic components, beginning with their design and providing the customer with support through each design stage. The company is accustomed to managing all the stages required for production.

Beginning with the analyses, using the latest simulation software, Texi Plastic is able to provide all the specification required to overcome any criticalities in the manufacturing stage and assess the performance levels of the finished part. 3D scanning is an operation of reverse engineering used to reproduce the mathematics of the mould part and return out of production parts to production. On the other hand, modern 3D mould technology allows efficient prototyping at extremely competitive prices.

The close collaboration with the customer makes it possible for our technical department to define all the design specifications for the parts to be sent to production including, the ergonomic and mechanical aspects, the technical and aesthetic features, the functional requirements, placement of the inserts, the coupling systems and the exterior finish.

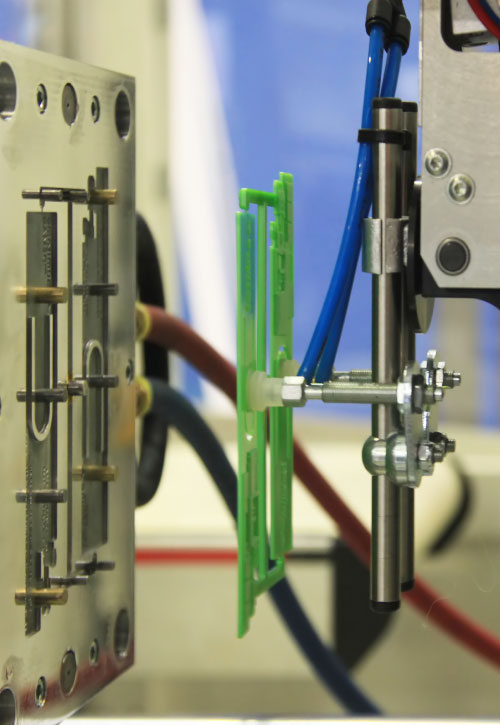

Texi Plastic has an internal plastic injection mould production department with latest generation presses capable of quick and efficient delivery of the finished product, ready to enter the market.

More information

Texi Plastic has its own mechanical workshop specialised in the manufacture of high quality moulds and is able to manage the entire industrial process.

More information